- Simple software concepts, minimizing set-up and programming times;

- Forming and shaping of carbide rods through external cylindrical grinding process, can also accomplish chamfering, tapering, corner rounding, plane processing, etc.;

- Ideal for processing complex tool geometries;

- High precision, high automation;

- Simple software concepts, minimizing set-up and programming times;

- Repeat accuracy of linear axis is 0.001mm;

- Fully automatic and un-manned operation;

- High accuracy in positioning;

- One clamping, can handle complex tool geometries;

- Simple software concepts, minimizing set-up and programming times;

- One clamping, can handle complex tool geometries;

- Fully automatic and un-manned operation;

- Can be used for both grinding and manufacturing of precision cutting tools;

- One clamping, can flexibly and quickly produce a wide variety of complex tools;

- Ergonomic design, easy to operate;

- High power of grinding spindle, high flexibility of tool design software;

- Fully automatic and un-manned operation;

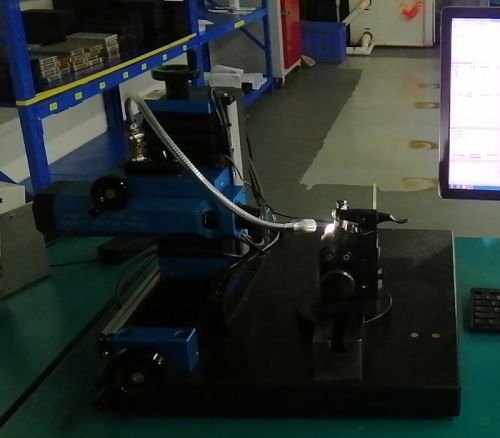

- Mainly applied for dressing of diamond and CBN grinding wheels (side, radius and face);

- Able to dress single wheel or multiple wheel packs;

- Easy to operate, high efficiency dressing, and high precision;

- Cutting tool edge preparation to extend tool life, aiming at increasing machining efficiency;

- Automatic operation;

- Easy to set parameters like working method, speed and depth-of-cut during the operation;

- Able to handle complex tool geometries;

- 5-axis CNC control, linear positioning accuracy 0.001mm, and rotatory positioning accuracy 0.01°;

- Robust structure with good shock absorption, stable and distortion-free construction;

- Pneumatic clamping unit, electrical fine adjustment;

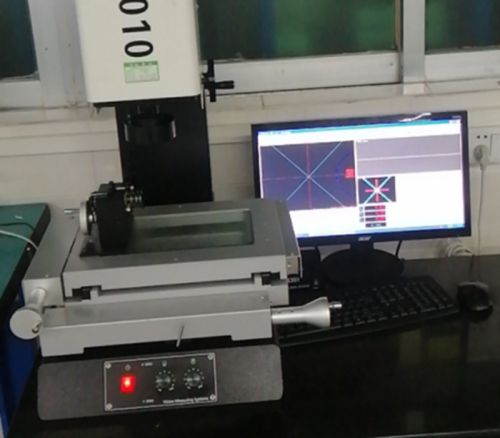

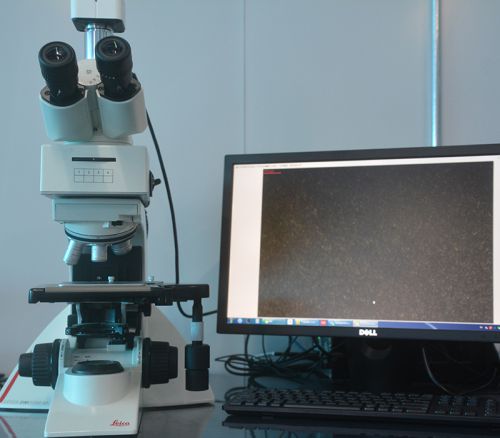

- High resolution magnification;

- Easy to operate;

It is used to precisely measure and test various parameters of cutting tools, such as rake angle, clearance angle, flank surface, nose radius, etc.

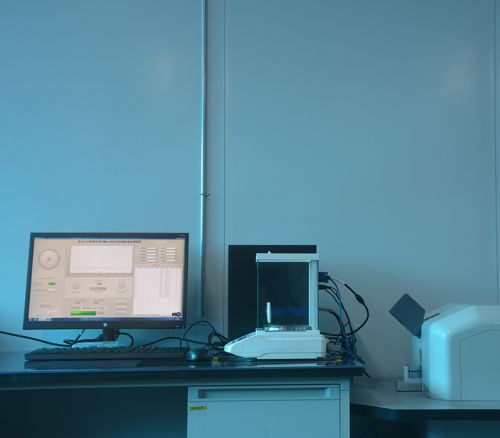

With high-resolution camera, this system can achieve high precision measurement of product size.

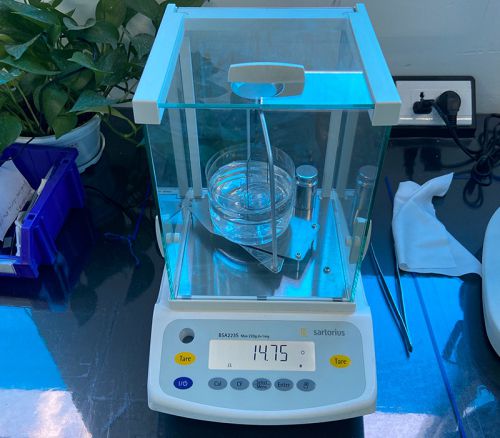

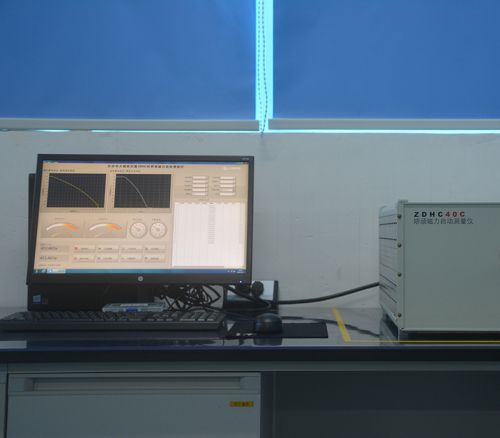

This unit aims at testing flexural strength of workpiece. In general, the more the cobalt content, the higher the flexural strength of the alloy.

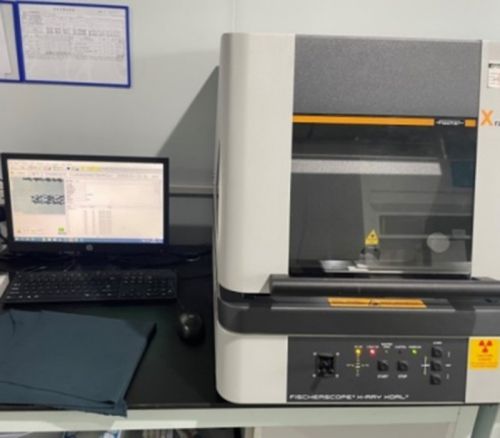

This testing system is a quick method to measure the thickness of tool coating.