Milling Inserts

Egret Tool focuses on engineering and manufacturing standard carbide inserts and providing solutions tailored precisely to customer's individual applications. All our carbide inserts including turning inserts, milling inserts and drilling inserts are manufactured using advanced equipment, such as PVD coating furnace, high-precision 5-axis grinding machine and more. Our experienced team of enthusiastic engineers who have worked in the cutting tools industry for over 10 years will look closely at customers' needs relating to cutting edge strength, sharpness and geometry, assisting customers in achieving excellent machining results, regardless of what industry customer is in.

-

- Double-sided Square Carbide InsertsThe double-sided square carbide insert is a face milling cutter with 8 cutting edges. The large rake angle design reduces cutting force, enabling the cutter suitable for light cutting of workpieces. The curved cutting edges allow smooth chip discharge, giving more stability for machining process.

-

- Double-sided Hexagonal Carbide InsertsThe hexagonal carbide insert is a type of cast iron milling cutters with 12 cutting edges. The high strength of cutting edge makes it an optimal choice for roughing to semi-finish face milling of cast iron workpieces.

-

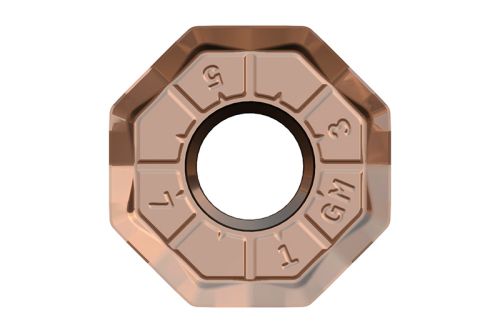

- Double-sided Octagonal Carbide InsertsThese double-sided octagonal carbide inserts are featured by 16 cutting edges, mainly used for roughing and finishing of general materials. The large rake angle design reduces cutting force, enabling the milling insert suitable for light cutting of workpieces. The curved cutting edges allow smooth chip discharge, giving more stability for machining process.

-

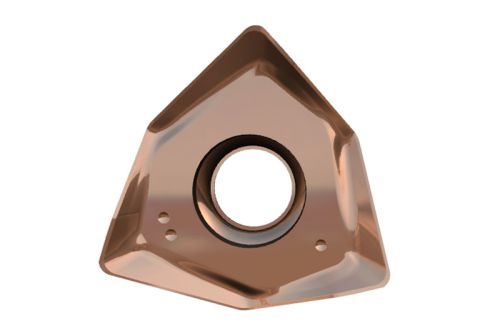

- Double-sided Trigon InsertsDouble-sided trigon inserts are characterized by convex cutting edge, providing optimum balance between strength and sharpness of the cutting edge. Large rake angle and large inclination angle ensure light cutting of workpieces and smooth chip discharge.

-

- Double-sided High Feed Milling InsertsDouble-sided high feed milling insert features very open geometry for high feed rates. The large rake angle design reduces cutting force, enabling the cutter suitable for light cutting of workpieces. The small entry angle ensures maximum high-feed milling capabilities, making the carbide inserts suitable for high feed milling of steel and stainless steel workpieces.